VM FLUIDIFIER (mini)

VM fluidizer (mini)

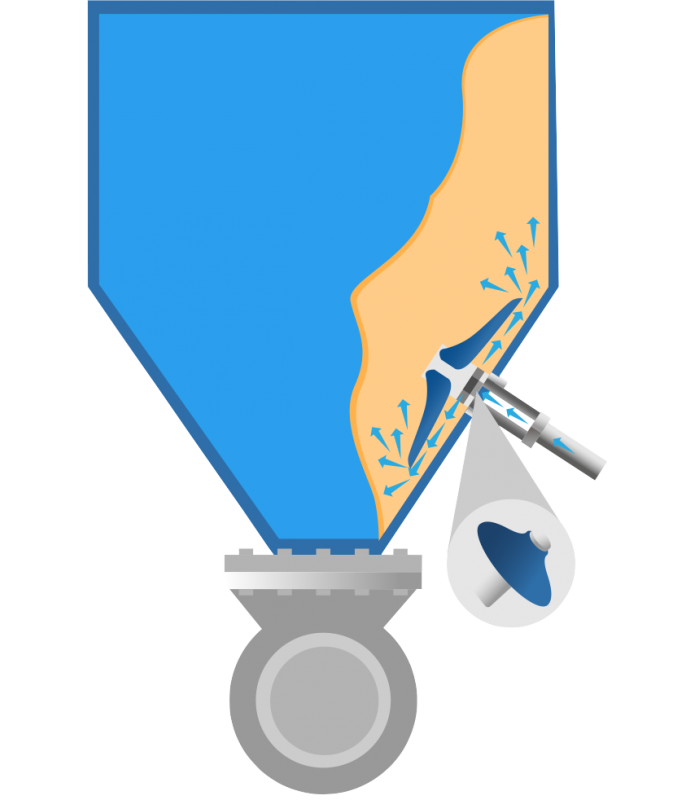

The VM model fluidizers combine the ventilation of the material at pressures up to 6 bars with a slight vibration of the tank or silo wall (see technical sheet to determine the size, placement and number). Due to the manufacturing materials used, damage to the silo structure is excluded (even with abrasive materials). An additional non-return valve is not necessary since, due to the working pressure of 2 to 6 bar (29-87 PSI), no material can enter the area under the elastic silicone lip (FDA approved). Thanks to FDA approval, vibro-fluidifiers are suitable for the food industry. To respond to more specific consumer requirements, a version with a stainless steel shaft (VBI) is available.

Operation: Compressed air is introduced into the material directly through the silicone lip adherent to the internal wall of the silo. The vibration intensity is regulated with the operating pressure included between 2 and 6 bars. Thanks to intermittent operation and a maximum duration of 5 seconds, air consumption is extremely low.

Data sheet:

- Robust design.

- Cleaning not essential.

- Abrasion resistant.

- Easy to install.

- Air pressure 2 to 6 bar (29 to 87 PSI).

- Ambient temperature from -40° C to 170° C (-40° F to 340° F).

- For powders and granular products.

- Consult price for quantities.