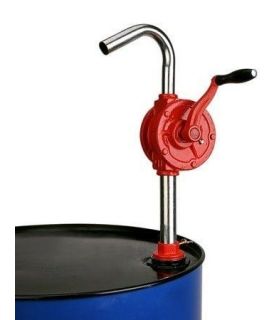

GREASE PUMPS ON TANK

Grease pump on tank. Buy with Free Shipping from €200

A reservoir Lubricationpump is a specific type of Lubricationpump used to supply lubricant from a centralized reservoir to multiple lubrication points in a machinery or equipment system. This configuration is commonly known as a centralized lubrication system. The operation can be in several ways, manual, using a lever, crank or pedal, electrical, by giving tension to a motor or pneumatic, using compressed air.

In a reservoir Lubricationpump system, the lubricant is stored in a central reservoir, which can be variable in size depending on the needs of the system. The Lubricationpump is mounted directly on the tank and is responsible for sucking the lubricant from the tank and supplying it through a network of pipes to the different lubrication points.

Normally the tank is associated with a tracking plate, intended to prevent the Lubricationfrom sticking to the walls of the tank. In this way, all the fat is used. This type of centralized lubrication system is particularly useful in industrial environments where there are multiple lubrication points dispersed over a large area. By using a centralized reservoir, the lubrication process is simplified and streamlined, eliminating the need for operators to carry lubricant to each point individually.

The tank Lubricationpump can be equipped with different types of controllers, such as timers, pressure sensors or level switches, which allow controlling the frequency and amount of lubricant supplied to each lubrication point. This guarantees precise and adequate lubrication for each component of the machinery or equipment.